The customer experienced motor stall and inability to operate normally after using the drive-controlled peristaltic pump, which negatively impacted their user experience.

When the customer controlled the peristaltic pump during operation, the motor experienced a stall, with the rotor unable to rotate properly and emitting abnormal noises..

Motor stalling, peristaltic pump unable to discharge liquid, customer cannot use normally.

1. When the peristaltic pump fails to operate normally, open the pump head and remove the pump tube to observe whether the motor can run properly under no-load conditions.

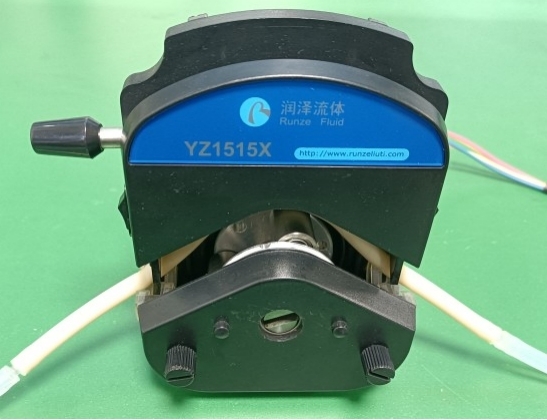

Taking the YZ1515X peristaltic pump as an example, release the tension lever to place the motor in a no-load state and control the motor operation.

2. If the motor still stalls under no-load conditions, check whether the motor wiring sequence is correct, and ensure there is no loosening or disconnection. Reconnect the motor wires and run the pump again. If it still fails to operate normally, it must be returned for inspection.

3. If the motor runs normally under no-load conditions, it indicates that the motor is functioning properly.

4. Pull down the tension lever and install the pump tube for a load test. If the pump operates normally, this indicates that the issue lies with the installation of the pump tube.

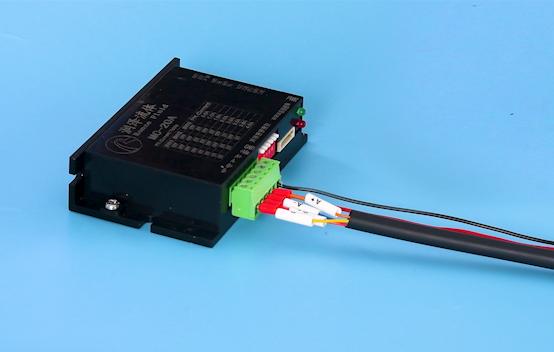

5. If normal operation cannot be achieved and the customer's driver is a product from our company, assist the customer in adjusting the current. Otherwise, recommend that the customer consult the driver manufacturer.

1. Before use, the customer should be informed of the motor's parameters, such as power rating, and the method for adjusting the output current on the driver.

2. It is recommended that the customer apply lubricant during initial use and after replacing the pump tube, and operate the pump at a low speed to ensure even distribution of the lubricant on the rotor and tube surface.

3. It is advised that the customer regularly check whether the connection between the motor wires and the driver is secure and free from disconnection.