Recently, Nanjing Runze Fluid Control Equipment Co., Ltd., based on extensive field application feedback, conducted an in-depth analysis of the flow direction control logic of multi-channel switching valves in automated fluid systems. As the "navigation core" of precision fluid systems, switching valves are widely used in medical testing, pharmaceutical processes, laboratory automation, and online analysis, where they are responsible for precise switching and distribution among different flow paths. However, during actual programming and system integration, many engineers face a critical debugging challenge: how to accurately predict and control the rotation direction of the valve core to reach the target position?

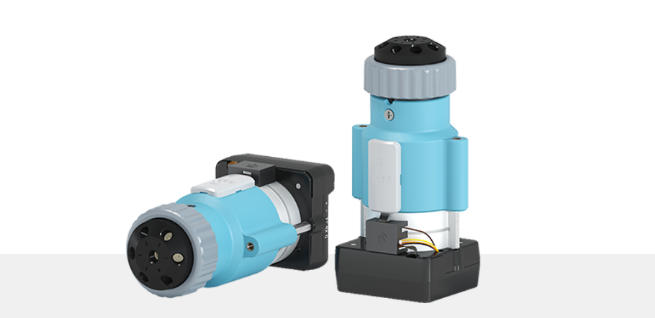

The physical core of a switching valve consists of a motor-driven rotating valve core (rotor) and a fixed valve body (stator). The motor receives pulse signals to control its rotation steps and direction, while the current position of the valve core is typically provided in real time by an encoder (magnetic or optical).

Therefore, the so-called "switching logic" essentially refers to the control algorithm calculating the required rotation direction and number of steps for the motor based on the current position, target position, and command parameters. Mastering the following key points unlocks the logic:

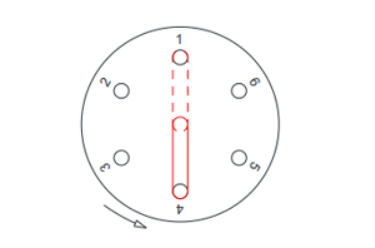

Home Position Benchmark: Upon power-up or reset, the valve must locate an absolute zero point (e.g., port 1).

Shortest Path Principle: In most cases, the system tends to rotate the valve with the minimal rotation angle (≤180°) to reach the target.

Command Priority: Specific advanced commands can override the "Shortest Path Principle" and enforce a specific direction.

Before programming or debugging the switching logic, please clarify the following points:

Valve Model and Number of Ports: For example, is it a 6-port valve, an 8-port valve, or a 10-port valve?

Encoder Type: Magnetic encoder or optical encoder? This affects the definition of the home position.

Communication Protocol and Command Set: Confirm whether you are using ASCII string commands or a binary/Modbus protocol, and prepare the corresponding command manual.

Mode 1: Default Home Position Logic

Operation: Send a home command (e.g., /1R or a specific home instruction) without specifying a direction parameter.

Behavior: The valve will rotate counterclockwise and return to the mechanical zero point (typically Port 1 for magnetic encoders, or the zero point for optical encoders).

Mode 2: Specified-Direction Home Position Logic

Operation: Include direction parameters (e.g., specifying clockwise homing) and target port parameters in the home command.

Behavior: The valve will strictly rotate in the direction specified by the command until it reaches the designated port.

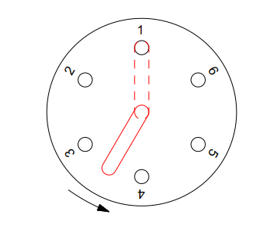

Mode 3: Optimal Path Switching Logic (Intelligent Mode)

Operation: Send a standard port switching command (e.g., from Port 1 to Port 4).

Behavior: The valve automatically calculates and selects the path with the smallest rotation angle. Special Note: When the current position and the target position are exactly 180° apart (diagonally opposite), the default behavior is counterclockwise rotation.

Example: For a 6-port valve switching from Port 1 to Port 4, the optimal path is counterclockwise through Ports 6 and 5 to Port 4 (90°), rather than clockwise through Ports 2 and 3 to Port 4 (270°).

Mode 4: Specified-Direction Switching Logic (Forced Mode)

Operation: Use advanced switching commands to explicitly specify the rotation direction (clockwise/counterclockwise) and the target (which can be a port or a position between ports).

Behavior: The valve ignores the shortest path and strictly rotates along the specified direction. This mode can even achieve stopping between two physical ports, which is useful for creating bypasses, performing system flushing, or special flow path control.

Example: Force the valve to rotate counterclockwise from Port 1, pass Port 3, and finally stop between Port 3 and Port 4.

In summary, the directional logic of switching valves combines intelligent defaults with flexible overrides. A clear understanding of its principles and the correct invocation of corresponding commands form the cornerstone of building a stable and efficient fluid automation system. When unexpected switching behavior occurs, first check which of the above modes the currently used command belongs to, as this will help quickly pinpoint the root cause.