Pre-torque Flangeless Fittings offer a unique connection for hand-tight fittings by clicks when the resistance of the cap increases until reached the correct torque, it is made of PP or PTFE material and come with a pre-torque nut and ferrule for gas or liquid transfer. These threaded fittings are available for tubing outer diameters of 1.6/2.0/2.5/3.0/3.2mm.

Nut Specification

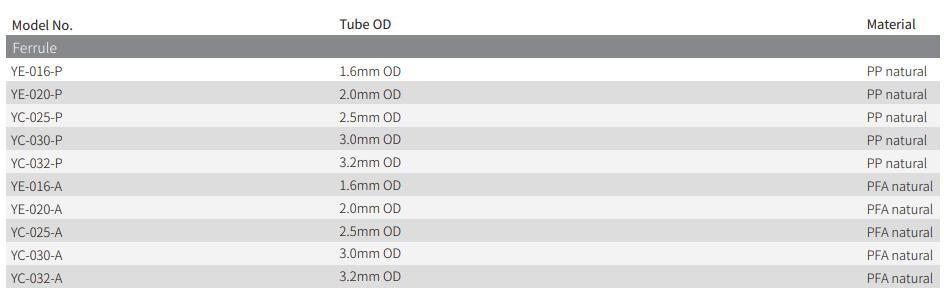

Ferrule Specification

Color | Blue | Yellow | Red | ||||

Nut |

|

|

|

|

|

|

|

Torque Range | 0.11-0.15N/m | 0.15-0.20N/m | 0.20-0.25N/m | ||||

Operating Environment | Room Temperature and Pressure Tube wall thickness≤0.5mm | Room Temperature and Pressure Tube wall thickness>0.5mm | Temperature<100℃ Pressure>0.8Mpa Tube WT>0.5mm | ||||

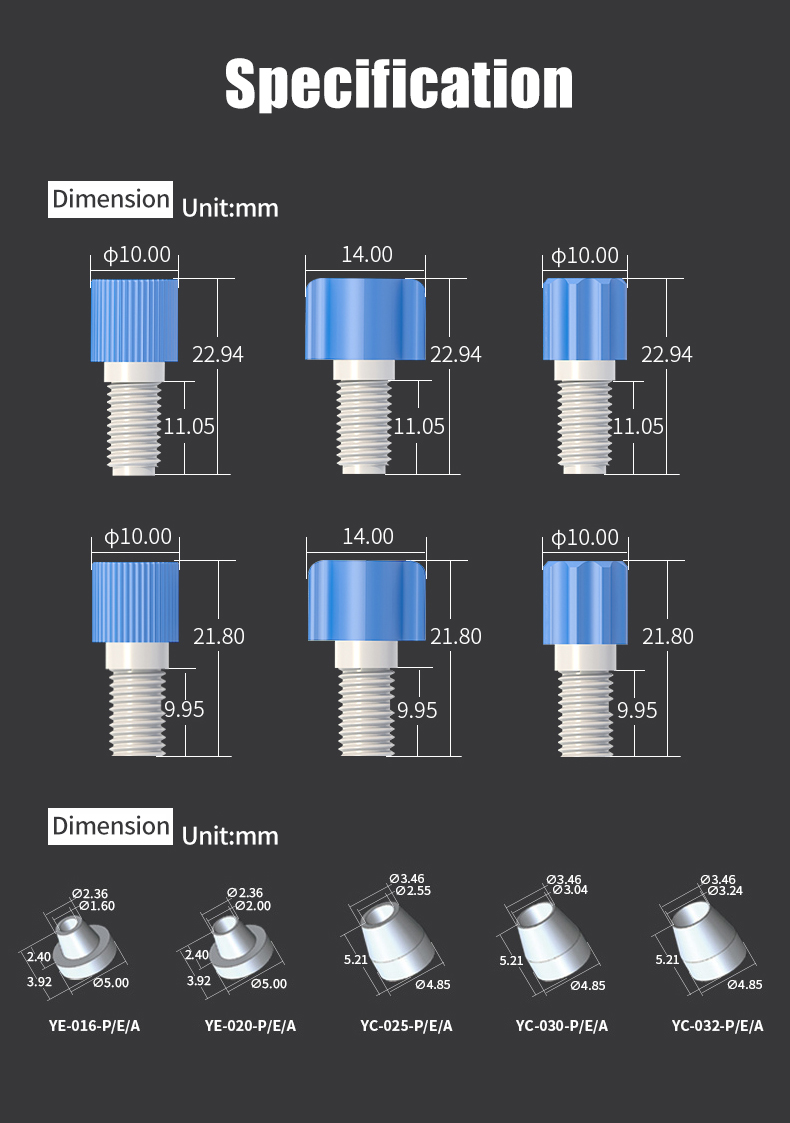

Dimension (unit: mm)

1. Choose 1/4-28 nut when receiving port is 1/4-28; Choose M6 nut when receiving port is M6.

2. Before connecting fittings, ensure the end of the tubing has a clean, square, burr-free cut. This is very important, as the square cut helps the tubing make full contact with the bottom of the mating port. Neglecting to properly cut the tubing could lead to dead volume, resulting in peak distortion such as fronting, tailing or broadening.

3. Two-Piece Fittings Installation Steps:

a. Slide the nut, followed by the ferrule, at least 3/16” (4.7625mm) from the end of the clean cut tubing

b. Insert the assembly into the receiving port, pushing the tubing into the port until it bottoms out.

c. Finger or wrench tighten the fittings until the cap comes out "click" which means properly tightened

d. After several uses (especially at high pressure) the ferrule should be replaced.