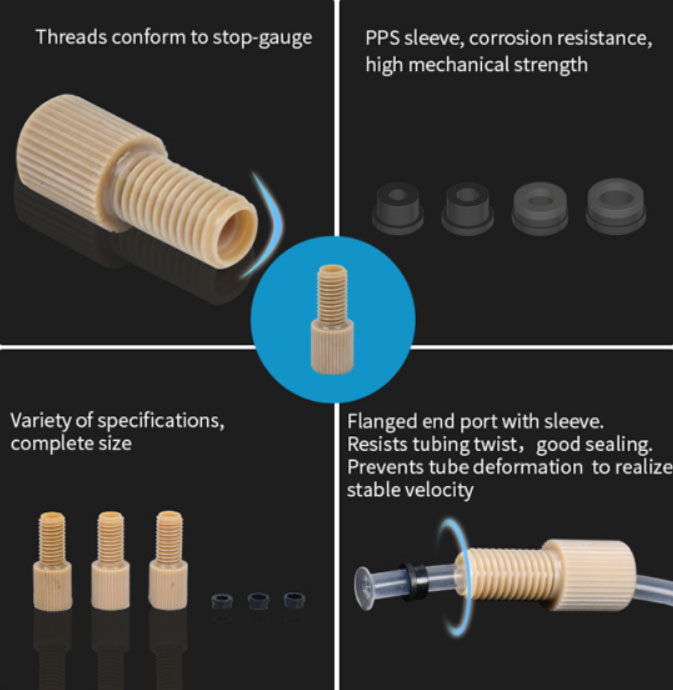

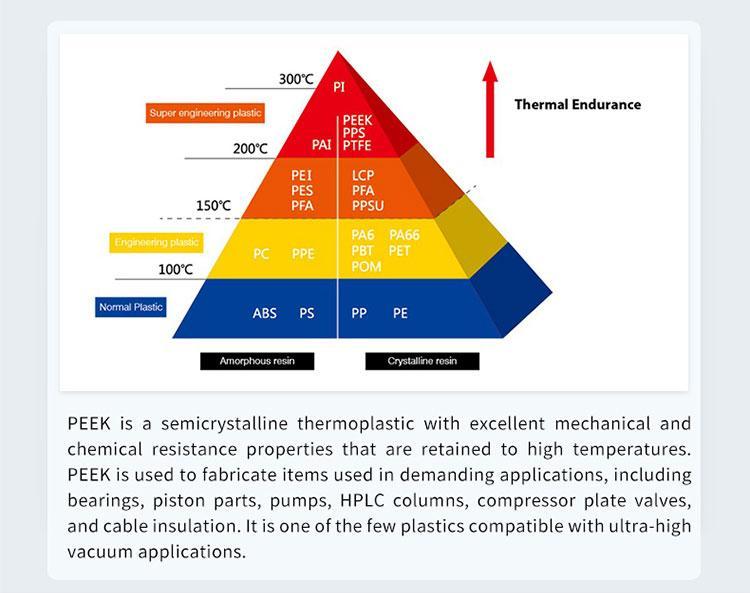

PEEK flanged fittings is one of the new products made by RUNZE, which combined with flanged joint and PEEK material superior performance. Flanged fittings is a traditional flat-bottomed fitting, By deforming the bottom of the tube, the bottom of the tube then compressed with the nut to form an airtight rigid tube connection system. With a PPS sleeve design, it can be disassembled repeatedly without affecting its sealing. PEEK is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. PEEK is used to fabricate items used in demanding applications, including bearings, piston parts, pumps, HPLC columns, compressor plate valves, and cable insulation. It is one of the few plastics compatible with ultra-high vacuum applications.

1. High coefficient of friction, better than PTFE in terms of impact resistance, etc.; high mechanical strength, fittings show no loosening after tightening.

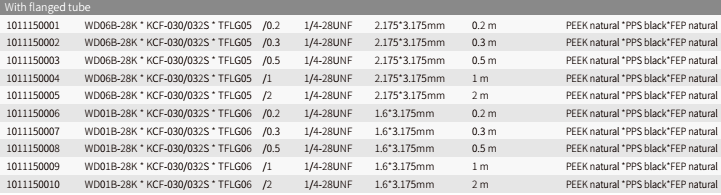

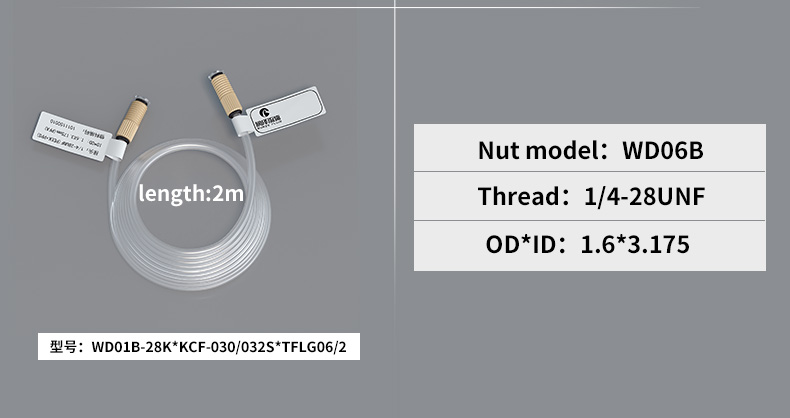

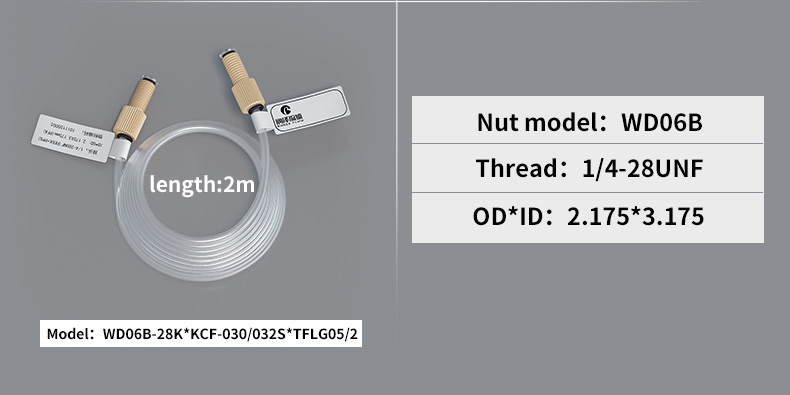

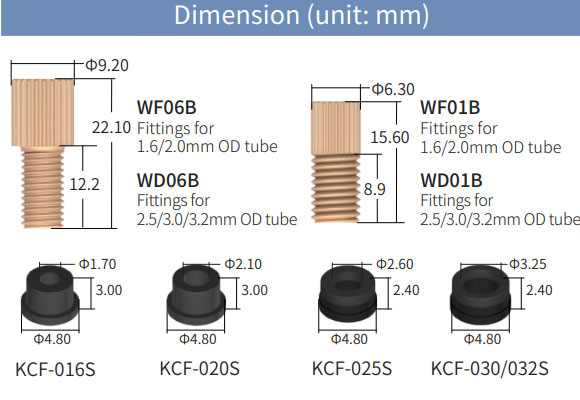

2. Can be used with 1.6/2.0/2.5/3.0/3.2mm OD rigid tubing can be disassembled repeatedly without affecting its sealing.

3. Prevent pipe deformation to realize stable velocity

4. Resist tubing twist when hand screwing

5. Frequent disassembly Supported

6. PEEK material, insoluble in almost all solvents except concentrated sulphuric acid. High Pressure and Corrosion resistance. Good aging resistance.

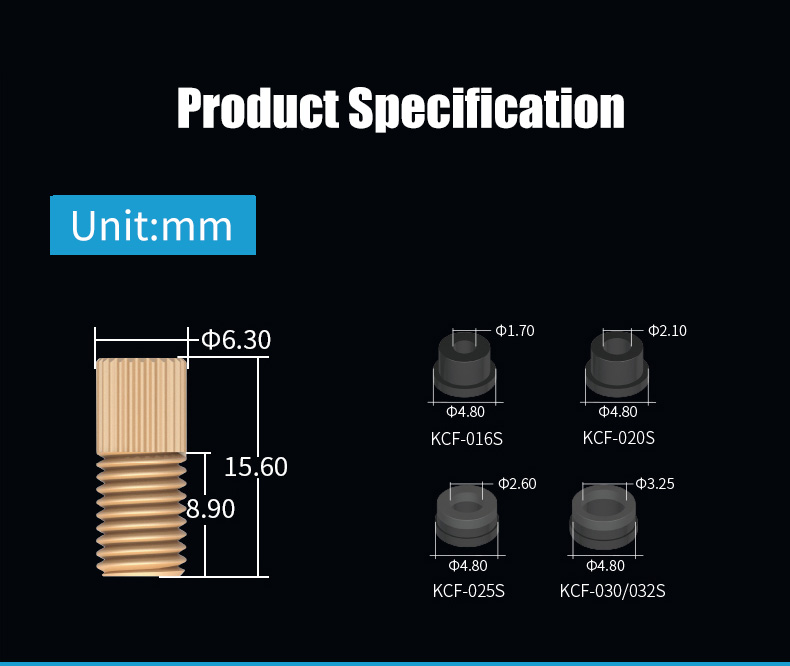

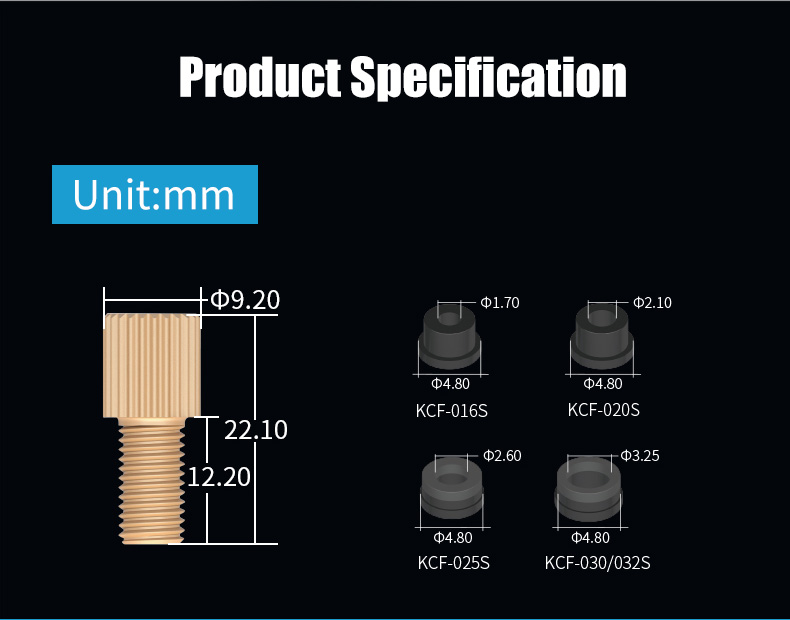

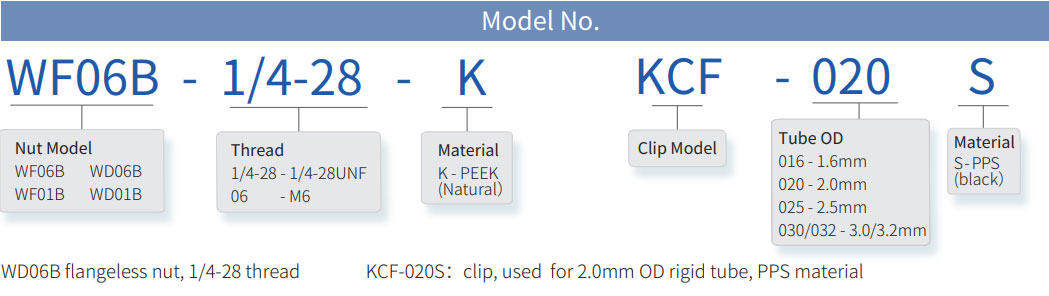

WF06B - 1/4-28 - K KCF - 020 – S

eg: WD06B flangeless nut , 1/4-28 thread

KCF-020S: Sleeve, used for 2.0mm OD rigid tube , PPS material

Before flange the tubing, ensure the end of tubing has a clean, flat-bottom, burr-free cut. This is very important, as it helps the tubing make full contact with the bottom of matching port. Neglecting to properly cut the tubing could lead to dead volume, resulting in peak distortion such as fronting, tailing or broadening.

Step 1. Flange the tubing with exclusive flange tools, tubing can be flanged one end or both two ends, depending on specific application requirements

Step 2. When tubing flanged in two ends, 2 pieces sleeves and 2 pieces nuts need to be slided into the tubing before both ends flanged; when tubing flanged in one end, 1 piece sleeve and 1 piece nut can be slided into tubing before or after the one end flanged.

Step 3. Insert the assembly into the receiving port, pushing the tubing into the port until it bottoms out

Step 4. Finger tighten the fittings into the port until snug

Note: Diameter of flanged tubing end ≤5mm