Independently developed high-precision micro-volume injection pumps, compatible with various distribution valves and injectors to meet the majority of user demands for high-precision fluid transfer.

◆ Supports multiple units for daisy-chain operation.

◆ Multi protocol control: ASCII code/custom/Modbus protocol

◆ Provides CE certification/RoHS reports.

As a core supporting component, it is applied in complete instrument solutions for laboratories, medical diagnostic and analysis equipment, chromatography analyzers, automated chemical analyzers, blood analyzers, microelement analyzers, electrolytic analyzers, food and beverage testing systems, water quality online analyzers, petroleum testing equipment, biological pharmaceutical extraction devices, and other high-precision, stable fluid transfer systems required for continuous process improvement

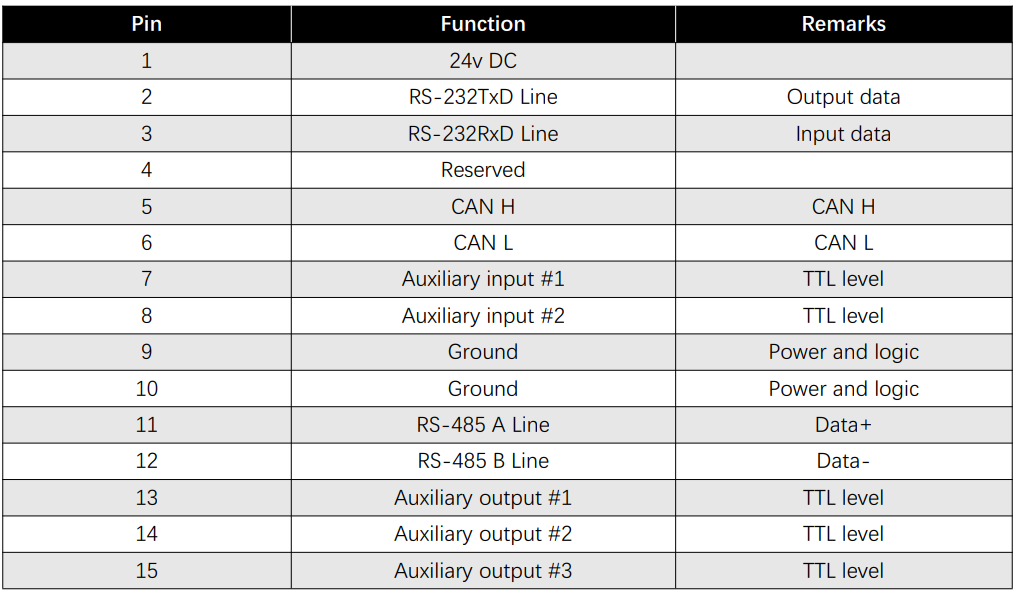

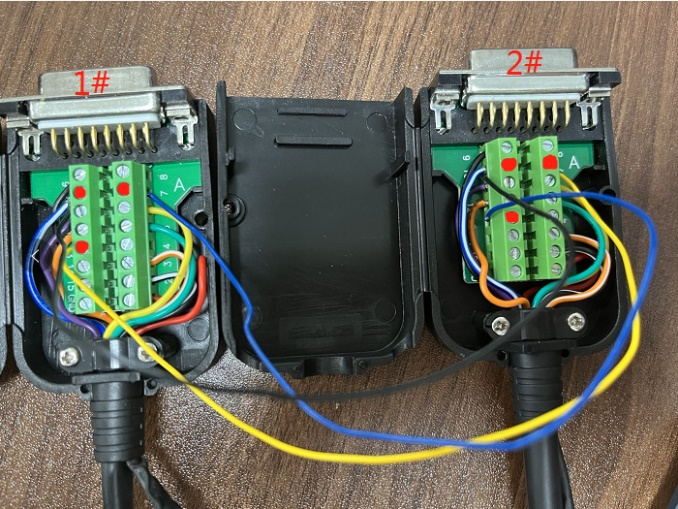

1. Hardware Principle: Utilize one TTL input (pin 7) and one TTL output (pin 13) of the device's DB15 connector to control the alternating operation of the two infusion pumps.

2. Test Principle: While Pump 1 is discharging, Pump 2 is set to refill relatively quickly and switch its valve port to the discharge port, waiting to discharge. When Pump 1's discharge volume is still a certain distance from zero, it triggers Pump 2 to start discharging. After Pump 1 finishes discharging, it quickly refills and switches its valve to the discharge port, waiting for the trigger signal from Pump 2. This mutual triggering between the two pumps achieves continuous liquid output.

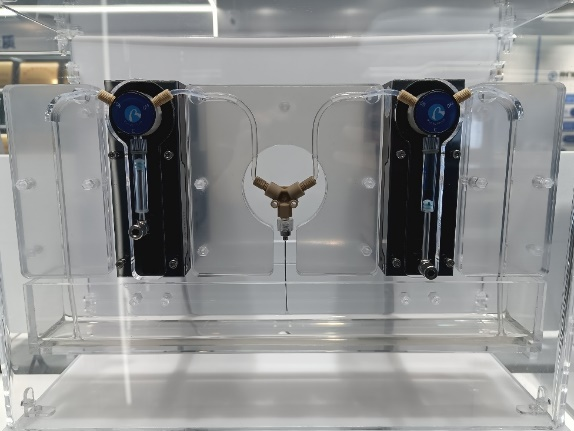

Use two SY-01B M01 model infusion pumps. Connect the ON port of Pump 1 and the OFF port of Pump 2 as liquid inlet ports, each attached with approximately 0.3m long PTFE hard tubes (1.6*3.2). Connect the OFF port of Pump 1 and the ON port of Pump 2 as liquid outlet ports, each attached with approximately 0.1m long PTFE hard tubes (1.6*3.2). At the end of the outlet ports, use a Y-shaped three-way connector to screw the two outlet tubes together. Attach a Luer needle to the end of the Y-shaped connector to observe the liquid output from the infusion pumps.

Note: Use three wires of different colors, each approximately 0.2 meters long (the length can be adjusted as needed). Connect the input (pin 7) of Pump #1 to the output (pin 13) of Pump #2; connect the output (pin 13) of Pump #1 to the input (pin 7) of Pump #2; and connect the GND (pin 10) of Pump #1 to the GND (pin 10) of Pump #2.

1. Set the address switches of the two pumps to "0" and "1" respectively.

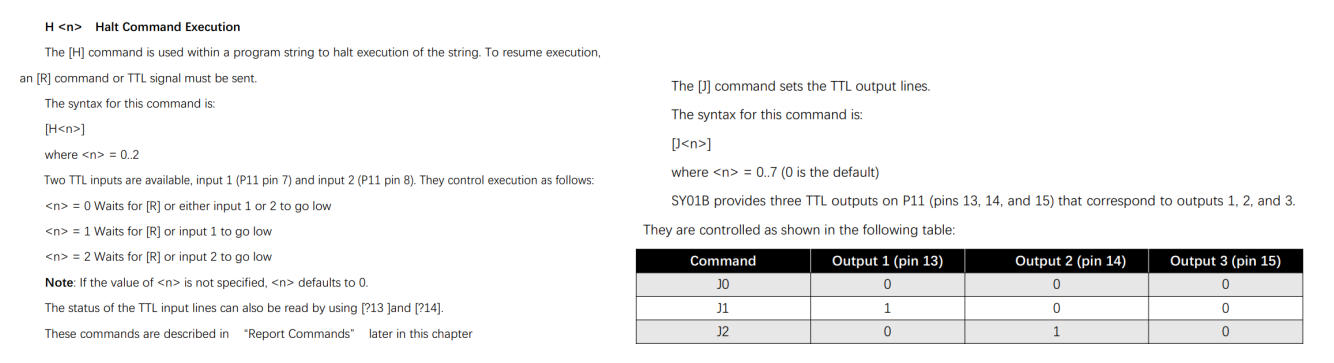

2. On the device with address "0", write the command: /1s0ZJ1IV6000A12000OJ0V2500A20J1A0J0IV6000A12000OgH1J1V2500A0J0IV6000A12000OGR

3. On the device with address "1", write the command: /2s0ZH1IV6000A12000OgH1J1V2500A20J0A0IV6000A12000OGR

4. First, use the command /1e0R to trigger Pump 1 to reset and execute its related commands. Then, use the /2e0R command to trigger Pump 2 to reset and wait for Pump 1 to trigger its subsequent actions

The SY-01B infusion pump can achieve stable and continuous liquid output in a dual-pump configuration.