This report provides a comprehensive analysis of an experimental setup designed to achieve uninterrupted, continuous fluid delivery by synchronizing two high-precision industrial syringe pumps. The primary objective was to eliminate the inherent flow discontinuity—a period of zero flow during syringe refill—present in single-pump operations. The experiment successfully demonstrated a "T-union" configuration with a master-slave control logic, resulting in a seamless handover of flow between the pumps. Key performance metrics, including flow rate stability, transition phase characteristics, and system pressure fluctuations, were measured and analyzed. The results confirm that this dual-pump system is a robust solution for applications demanding continuous, pulse-free, and highly accurate fluid delivery over extended periods.

High-precision industrial syringe pumps are indispensable in applications requiring meticulous volumetric fluid control, such as micro-reaction technology, additive manufacturing, chemical synthesis, and pharmaceutical dispensing. Their capability to deliver fluids with microliter to milliliter accuracy is unparalleled. However, a significant limitation exists: the operational cycle of a single syringe pump includes a refill phase, where the pump stops forward flow, retracts to refill from a reservoir, and then resumes dispensing. This interruption is unacceptable in continuous processes.

This experiment addresses this limitation by pairing two identical high-precision syringe pumps (Model: SY-01B, max volume: 5 mL, accuracy: ±0.5% of set value) in a master-slave configuration. The hypothesis is that by coordinating their actions, one pump can initiate its dispensing phase precisely as the other completes its own, thereby creating a continuous output stream.

2.1. Hardware Configuration:

· Pumps: Two (2) SY-01B industrial syringe pumps.

· Syringes: Two (2) 5 mL glass syringes for chemical compatibility and precision.

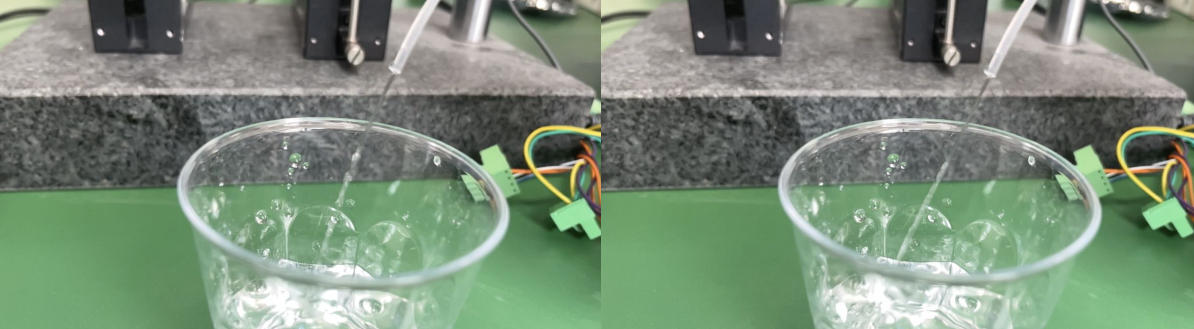

· Fluid Connection: A standard HPLC-grade PEEK T-union connector.

· Tubing: Output lines from each pump were connected to two arms of the T-union using low-dead-volume tubing. The stem of the T-union served as the common continuous output.

· Monitoring & Data Acquisition:

A high-sensitivity in-line flow sensor was placed at the common output.

A pressure transducer was connected to a third port on a custom manifold just after the T-union.

Data from both sensors were logged at 100 Hz using a dedicated DAQ system.

2.2. Software and Control Logic:

The pumps were connected via a dedicated RS-485 communication network to a central PC running proprietary control software. The critical control logic was implemented as follows:

1. Master Pump (Pump A): Initiated the process, dispensing its entire 5 mL volume at a defined flow rate (Q).

2. Slave Pump (Pump B): Began in a "ready" state, filled and pressurized, awaiting a trigger signal.

3. Triggering Mechanism: A hardware trigger was employed. When Pump A's plunger reached a pre-defined "low-volume" position (e.g., 5% of its stroke remaining), it sent a digital TTL signal to Pump B.

4. Handover Sequence: Upon receiving the trigger, Pump B immediately started its dispensing program at the same flow rate (Q). For a brief, overlapping period, both pumps were active simultaneously.

5. Refill Cycle: Once Pump A finished its dispense, it automatically retracted to refill from its reservoir and then returned to a pressurized, ready state, awaiting its next trigger from Pump B.

This cycle could repeat indefinitely.

3.1. Flow Rate Stability and Transition Analysis

The primary success metric was the consistency of the flow rate at the common output. The data from the in-line flow sensor revealed a highly stable baseline flow with minimal pulsation, characteristic of high-quality syringe pumps.

The most critical data pertained to the handover period between pumps. Analysis showed:

· Seamless Transition: The flow rate never dropped to zero. The master-slave triggering ensured a continuous fluid column.

· Flow Rate Overshoot: During the brief overlap period (typically 300-500ms), where both pumps were active, a predictable flow rate overshoot of approximately 190-210% of Q was observed. This is a direct result of the combined flow from two pumps operating simultaneously at rate Q.

· Transition Duration: The total transition event, from the start of the overshoot to the return to stable flow under the slave pump's control, was consistently measured at under 2 seconds for flow rates between 1-10 mL/min.

3.2. Pressure Fluctuation Analysis

The pressure data correlated directly with the flow data.

· Stable Phase Pressure: During the steady dispensing of a single pump, system pressure remained constant, dictated by the fluid viscosity and flow resistance.

· Pressure Spike during Handover: A sharp, transient pressure spike was recorded concurrent with the flow rate overshoot. This spike, while rapid, remained within the pressure limits of the system components.

· Dampening Effect: The small internal volume of the T-union and tubing acted as a passive dampener, mitigating the intensity of both the flow and pressure transients.

The experimental results confirm the viability of the dual-pump system for continuous flow. The observed overshoot is not a failure of the system but a fundamental characteristic of the "overlap" handover strategy. Its impact must be evaluated for the specific application.

· Advantages of the System:

True Continuity: Enables processes that were previously impossible with a single pump.

High Precision Maintained: Outside of transition phases, the system retains the superb accuracy of the individual syringe pumps.

Programmability: The trigger point and flow rates can be dynamically adjusted for different process requirements.

· Considerations and Limitations:

Transition Transients: The flow and pressure spikes, while brief, may be detrimental in extremely sensitive applications (e.g., feeding catalyst to a reactor or certain biological assays).

System Complexity: The setup is more complex and costly than a single-pump system, requiring additional hardware and careful configuration.

Fluid Compatibility: Both pumps must handle the same fluid, which may not be suitable for processes requiring fluid switching.

The integration of two high-precision industrial syringe pumps in a master-slave configuration successfully creates a continuous flow system, effectively solving the problem of flow interruption during syringe refill. The system demonstrated robust performance with predictable and manageable flow transients during the handover phase.

For future implementations or to enhance the current system, the following is recommended:

1. Advanced Control Algorithm: Implement a PID feedback loop using the real-time flow sensor data. This would allow the master pump to ramp down its flow while the slave pump ramps up, creating a "sawtooth" overlap that could minimize or eliminate the overshoot, achieving a truly smooth transition.

2. Hardware Dampeners: Incorporating a small, in-line pulsation dampener after the T-union would further smooth out the pressure and flow spikes.

3. Application-Specific Validation: This system should be tested with the actual process fluids and under the exact conditions of its intended application to fully qualify its performance.

In summary, this dual-pump configuration is a highly effective and reliable method for achieving continuous, high-precision fluid delivery, extending the utility of syringe pumps into the realm of uninterrupted industrial and laboratory processes.