Lubricating fluid

Injection pump

Switching valve

Peristaltic pump

Joint pipeline

OEM customization

PEEK inverted cone connector

Runze's new connector is launched

Corrosion resistance, high-temperature resistance and high-pressure resistance

PEEK connector & ETFE pressure ring

New breakthrough in Runze: PEEK inverted cone joint

Runze fluid connector family has added a new member: PEEK inverted cone connector!

Recently, Runze Fluid has mass-produced a new type of inverted cone connector, filling the gap of PEEK material for Runze connector, and enriching the material and product types of Runze connector. After the expansion, the richer and more mature product line of Runze allows customers to have more and more free choices, so that customers can reduce production costs, save research and development time, and improve work efficiency.

Outstanding advantages: PEEK structural performance

The PEEK connector is the most commonly used fluid transmission accessory. It solves the conversion from macro fluid to micro fluid through the simplest method. The method of use of this connector is simple with low cost and the not-high requirements for operators.

PEEK has excellent chemical resistance, thermal stability and oxidation resistance, as well as good mechanical strength, creep resistance and electrical properties. It can withstand high-energy radiation, has good flame retardancy, strong tolerance, and will not contaminate fluid samples. The long-term working temperature of PEEK can range from -100°C to +250°C. Compared with other high-temperature resistant plastics such as PI, PPS, PTFE and PPO, the upper limit of the operating temperature exceeds about 50°C.

PEEK connectors are widely used in liquid phase, gas chromatography, laboratory analytical instruments and other equipment.

It is resistant to hydrolysis. Its excellent properties can be maintained under high temperature and high pressure.

Radiation resistance and stable insulation.

Corrosion resistance, anti-aging, only soluble in concentrated sulfuric acid at room temperature.

It can be repeated high temperature and high-pressure sterilization

Its larger rigidity creates good dimensional stability, which is close to metal aluminum material.

Is it highly priced? PEEK fittings are expensive because of the expensive synthetic monomer raw materials and the harsh reaction conditions, which makes the cost high.

The two main monomers required for PEEK polymerization, 4,4'-difluorobenzophenone and hydroquinone, are expensive. In addition, the PEEK polymerization process must ensure the reaction in an oxygen-free state while the reaction temperature is as high as 310-340°C. In order to obtain PEEK resin with higher purity, it is necessary to carry out tens of times of alcohol refinement process and water washing process on the crude product. As a result, PEEK raw materials are expensive. Generally, domestic PEEK is several hundred yuan per kilogram, and imported PEEK exceeds 1,000 yuan per kilogram.

High processing technology requirements

PEEK has good processing performance. However, because the melting point of PEEK is as high as 343°C and the adhesion of PEEK is relatively strong, the material and structure of the barrel, screw, mold of the molding equipment, and the temperature control requirements of the equipment are relatively high.

Variety of products makes high early-stage research and development costs.

To meet the requirements of various working conditions of customers, not only the commonly used carbon fiber reinforced, glass fiber reinforced and other basic grades, but also anti-static grades, conductive grades, wear-resistant grades and high-strength grades are required. At the same time, it also needs the structural design, mold design, process design, mold test and a lot of research and development work.

High product requirements and many processing procedures

Because PEEK materials are expensive, customers have relatively high requirements for finished products such as strictly controlling appearance quality, tolerances and surface finish. Some products have complex structures, so there are many processing procedures and many personnel to be involved, resulting in increased costs.

The PEEK joints produced by Runze are all formed at one time by imported expensive injection molding machine equipment. The joints produced are guaranteed to have high accuracy, high shipping efficiency, low defective products, and stable supply. Interested partners are welcome to come and consult!

Runze PEEK inverted cone connector

1. Material advantage

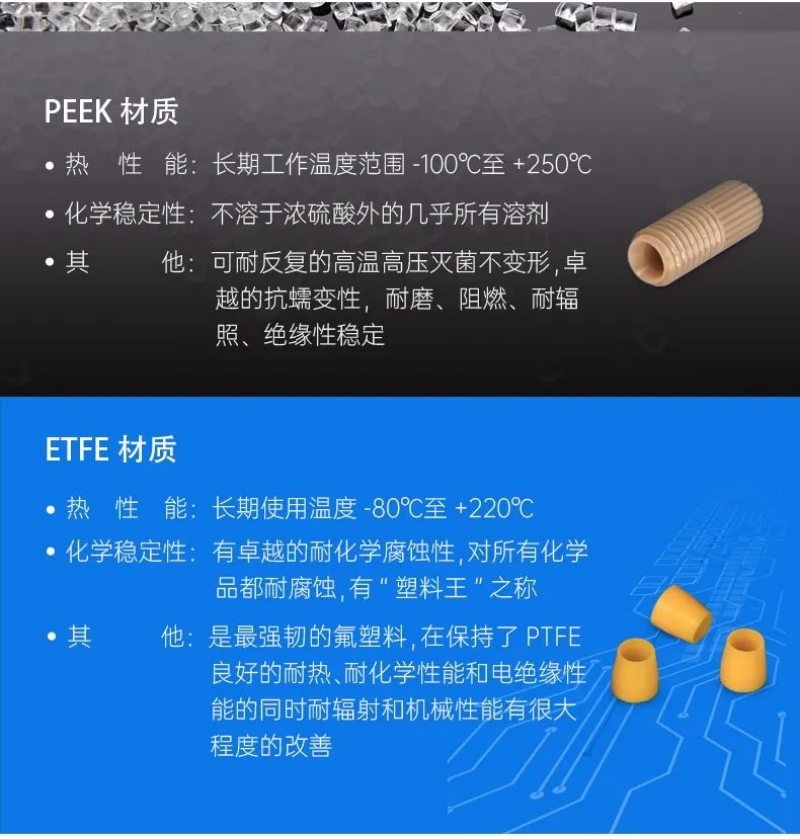

PEEK material

Thermal performance: long-term working temperature range -100℃ to +250℃

Chemical stability: insoluble in almost all solvents except concentrated sulfuric acid

Others can withstand repeated high temperature and high pressure sterilization without deformation, excellent creep resistance, abrasion resistance, flame retardant, radiation resistance and stable insulation.

ETFE material

Thermal performance: long-term use temperature -80℃ to +220℃

Chemical stability: excellent chemical resistance, corrosion resistance to all chemicals, known as the "Plastic King"

Others: It is the strongest fluoroplastics, while maintaining the good heat resistance, chemical resistance and electrical insulation properties of PTFE. The radiation resistance and mechanical properties are greatly improved.

2. Application scenarios

Laboratory

Medical analysis

environmental test

Food Testing

Biochemical analysis

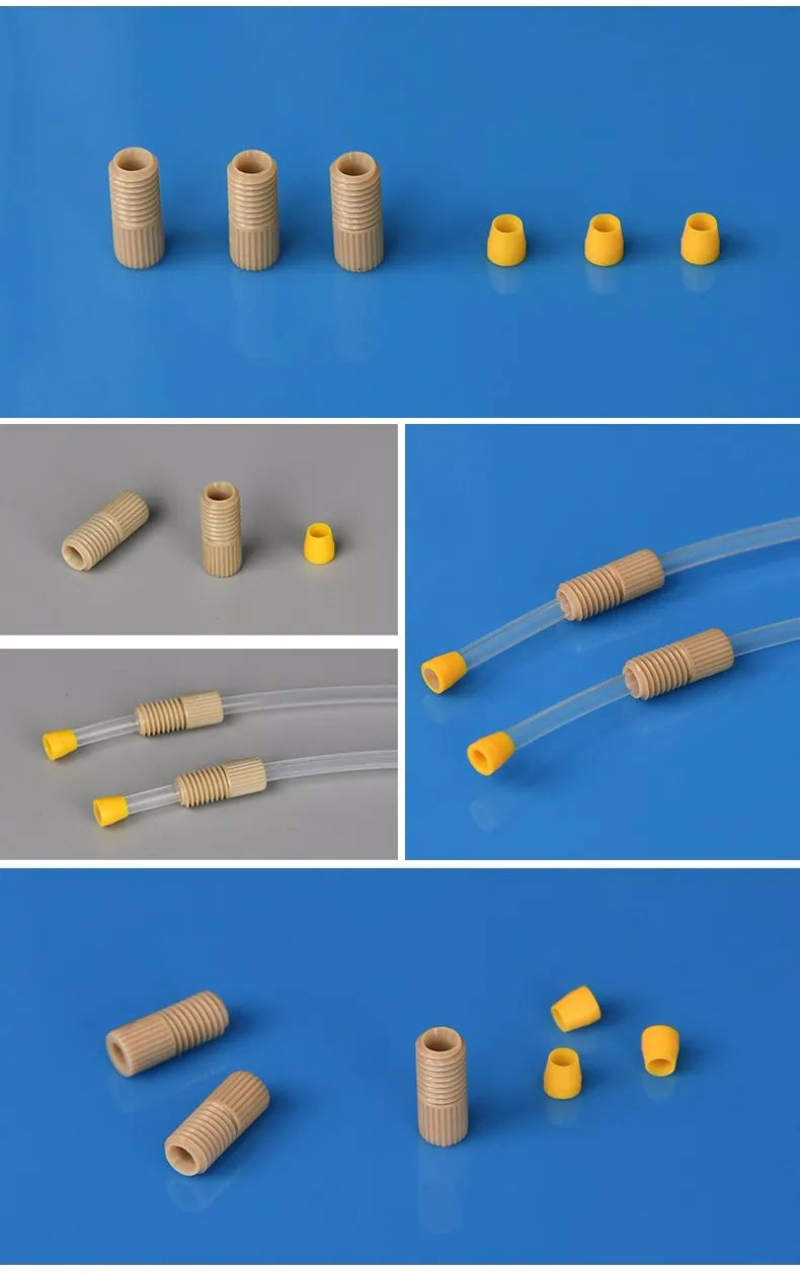

3. Joint real shot

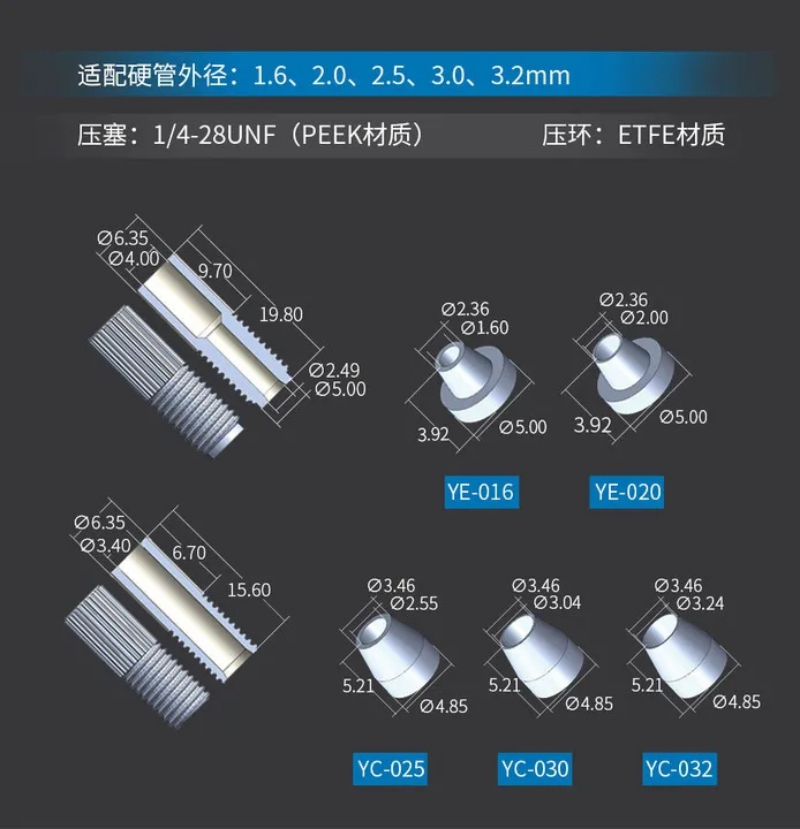

4. Product model

Adapted hard tube outer diameter:

Pressure plug: 1/4-28UNF (PEEK material)

Pressure ring: ETFE material