How to Determine the Switching Orifice Accuracy in a Magnetic Encoder Switching Valve

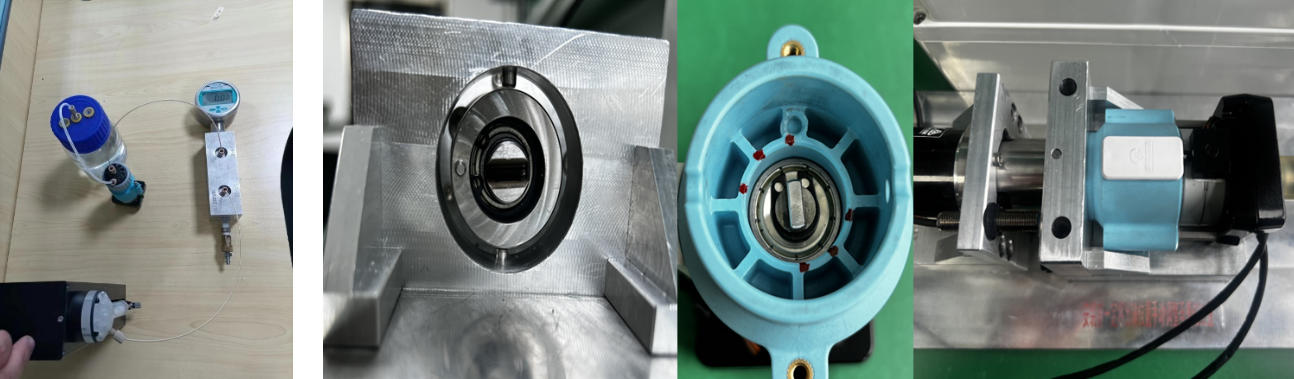

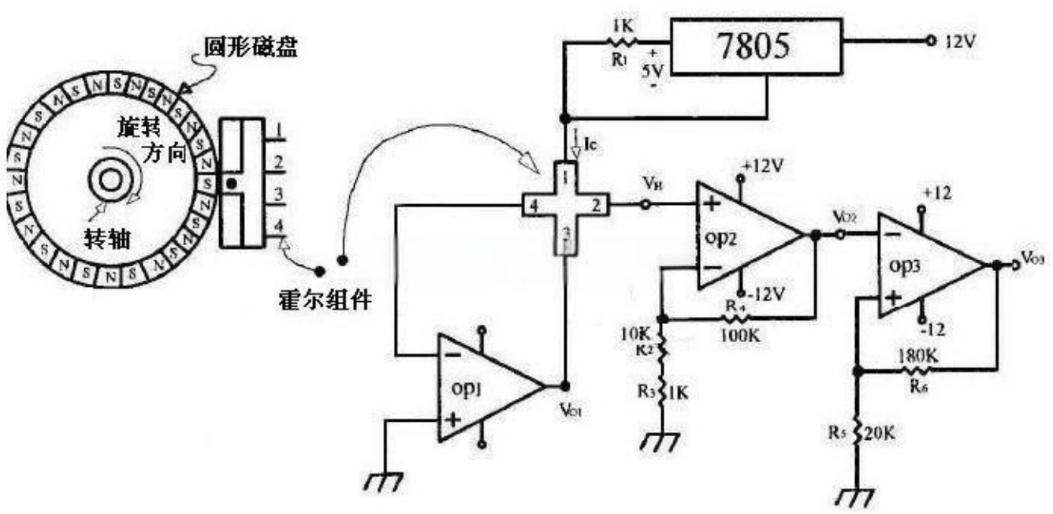

Absolute Magnetic Encoders utilize a magnetic scale to measure position or angle. The magnetic scale contains a series of north-south magnetic poles, while the sensor comprises an array of magnetic sensing elements that detect changes in the magnetic field on the scale.

As the rotating part moves, the magnetic field on the scale changes accordingly. The sensor converts these variations into electrical signals, which are then processed by associated electronic components. Ultimately, these electrical signals are transformed into digital signals representing position or angle information.

No Homing Required: Absolute encoders can directly provide accurate position or angle information, eliminating the need for a homing or reset procedure upon power-up.

High Accuracy: They deliver highly precise position or angle measurements, typically characterized by a very small error margin.

High Resolution: Absolute encoders provide high-resolution position or angle data, making them suitable for applications demanding exceptional precision.

High Reliability: Utilizing a non-contact measurement method (no physical contact with the measured object, which significantly reduces wear and tear and minimizes impact on the object), they offer high reliability and durability

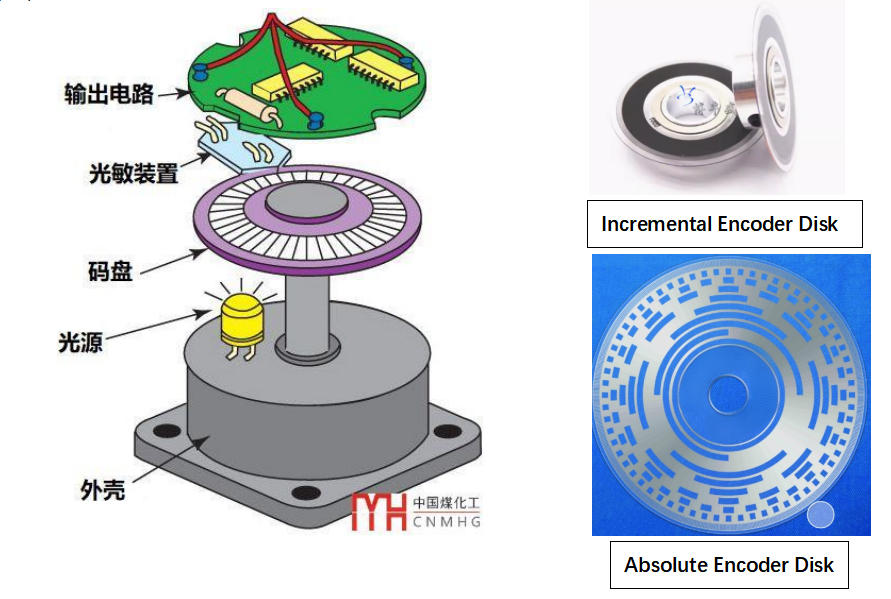

A photoelectric encoder is a sensor that detects information such as an object's position, angle, and rotational speed based on the transmission or interruption of light. These encoders are widely used in robotics, motor control, industrial automation, and other fields. Photoelectric encoders are generally categorized into two main types: incremental and absolute.

Incremental Photoelectric Encoders

Incremental photoelectric encoders provide information about changes in position but do not offer absolute position data. They consist of a light source (typically an LED), an encoded disk (a transparent disc with a pattern of alternating transparent and opaque lines), and a photodetector.

When the encoded disk rotates, the alternating transparent and opaque stripes pass through the light source, generating pulse signals. Photodetectors, such as photodiodes or phototransistors, detect these pulse signals, which are then decoded to determine rotational speed, direction, and the extent of angular displacement.

Absolute Photoelectric Encoders

Absolute photoelectric encoders provide absolute position information, with each angular position corresponding to a unique code. They can retain position data even after a power loss. These encoders employ an optical system similar to that of incremental encoders, but the design of the encoded disk is more complex, typically featuring multiple concentric tracks. Each track represents a different position in binary code along the same circle.

As the encoded disk rotates, the stripe patterns on each concentric track are detected by corresponding groups of photodetectors. The light signals are converted into binary electrical signals, and the combination of these signals represents a unique position.

Advantages

High Accuracy and Resolution: Photoelectric encoders can provide very high resolution, enabling extremely precise detection of angular changes. This is particularly true for absolute photoelectric encoders, which assign a unique code to each position.

Fast Response: These devices can detect positional changes almost instantaneously, making them ideal for applications requiring rapid response.

Long Lifespan and High Reliability: They eliminate issues related to contact-based wear. Since they utilize light to detect position, they generally offer a long service life and high reliability.

Digital Output: Photoelectric encoders provide direct digital signals, making them well-suited for digital control systems and computer interfaces.

Good Environmental Resistance: Many photoelectric encoders are designed to withstand dust, moisture, and other environmental conditions, despite their optical components.

Disadvantages:

Optical Components are Vulnerable: The internal components of photoelectric encoders, particularly the optical elements, are sensitive to dust, contamination, and scratches, which can compromise the encoder's performance and accuracy.

Higher Cost: Photoelectric encoders are generally more expensive to purchase and maintain compared to mechanical or magnetic encoders.

Requires a Power Supply: They require an external power source to operate the internal light source, resulting in relatively higher energy consumption.

Sensitivity to Ambient Light: Their performance can be susceptible to interference from external light sources, especially direct sunlight.

Complexity and Installation Demands: They often require precise installation and alignment to ensure the optical path is correct, increasing the complexity of both setup and maintenance.

Sensitivity to Temperature: High temperatures can adversely affect the performance of the photoelectric components, thereby impacting the overall system accuracy.

Therefore, Runze's absolute magnetic encoders undergo special processing, achieving precision that is nearly on par with photoelectric encoders. However, the absolute magnetic encoders offer distinct advantages: they require no homing, deliver high precision and resolution, and provide high reliability (maintaining accuracy even with dust or other substances on the code wheel). Under harsh field conditions, they consistently sustain precision and minimize angle inaccuracies caused by interference.

Based on the above description, our company's absolute magnetic encoder switching valves, after technical enhancements, have resolved the previous issue of misaligned orifices caused by inaccurate positioning. This inaccuracy was common with photoelectric encoders due to environmental factors (such as interference from dust, reagents, or oil on the code disk) and signal interference. Furthermore, the accuracy of the absolute magnetic encoder can now match that of photoelectric encoders.